With 5,200 sq/ft of industrial manufacturing premises in Bristol.....

....OMS is a multi disciplinary group comprising all the elements necessary to successfully manage the design and manufacture of fabric structures.

Our in-house knowledge, experience, machinery and capacity means we can offer manufacturing services ranging from bespoke one-off and prototype design / development to large scale mass production.

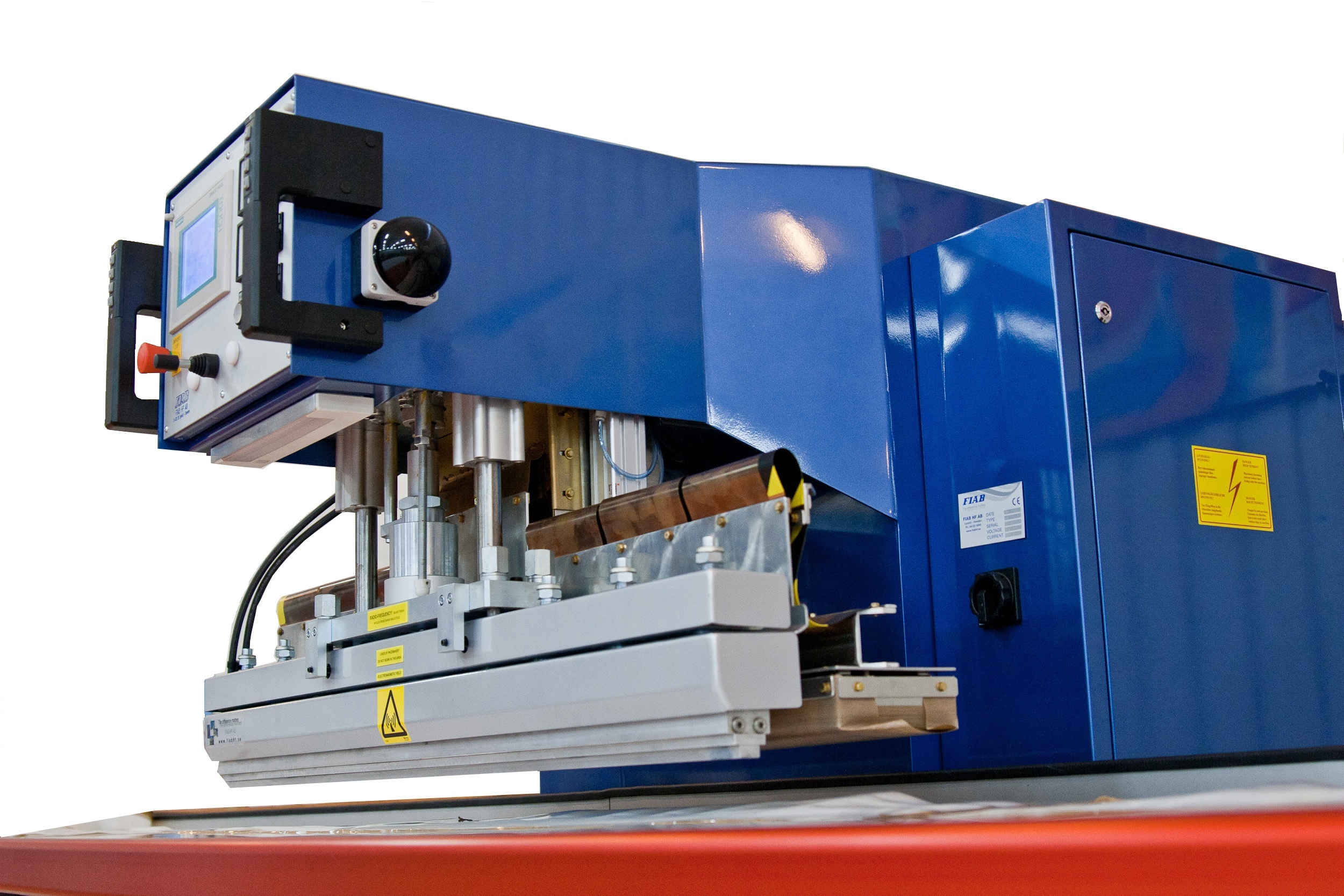

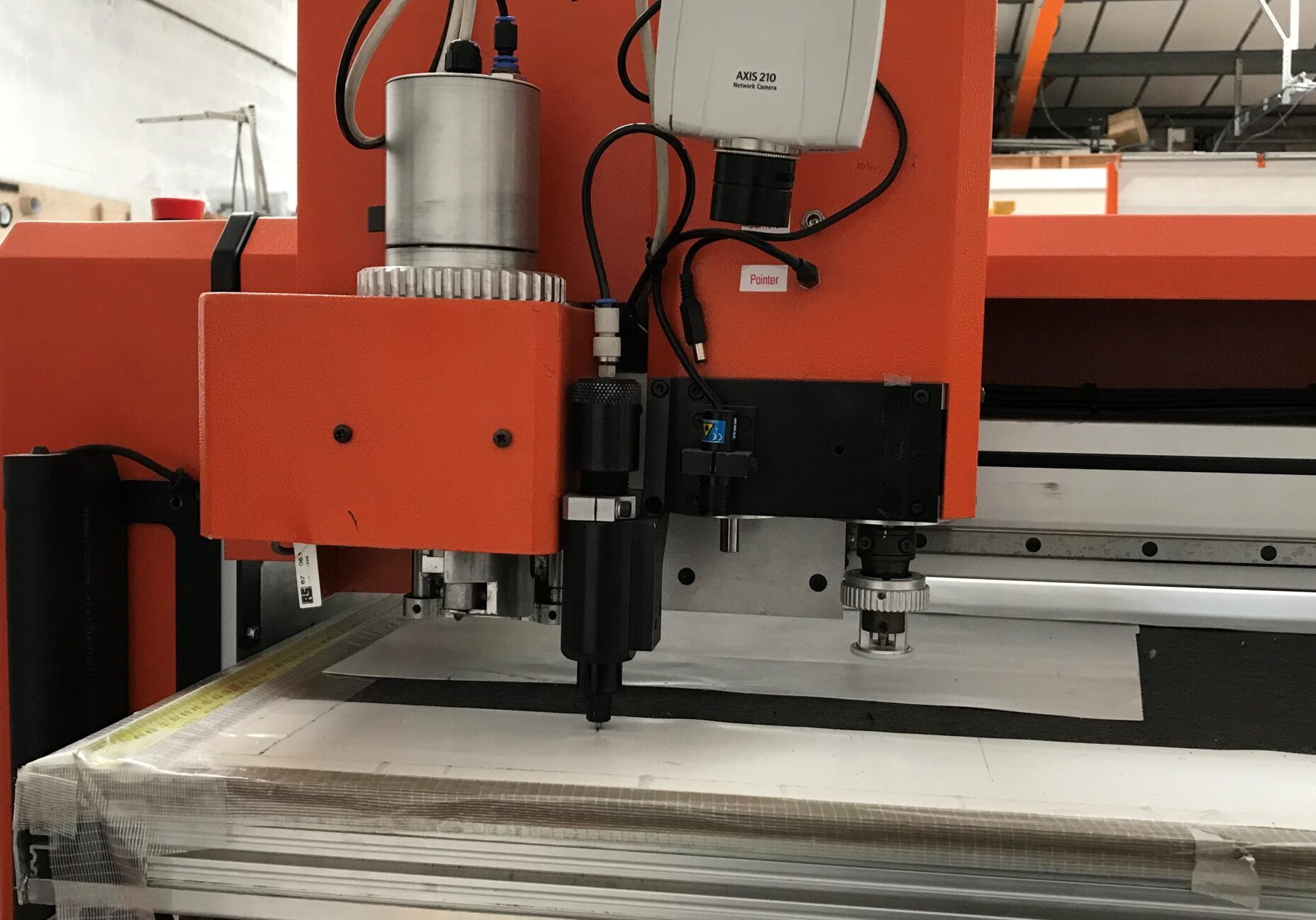

Our Blackman & White CAD plotter / cutter can accept fabric roll widths up to 3.2 metres wide x 300m long, with sewing machines aplenty allied with High Frequency welders, hot air, hot wedge and heated platen welders ensures we can weld, bond and join everything we cut

PARTNERSHIPS

Over the years OMS have enjoyed much success in developing close working relationships with leading enterprises such as:

Qshelters - The New, Safer Way to Queue

The Qshelter has been created as a quick to install, compact and inexpensive solution allowing the public to queue in comfort, irrespective of harsh sunshine or torrential downpours.

The Qshelter is a fully engineered, free- standing temporary structure designed to be installed with minimal disruption to business, requiring no on-site drilling, digging nor heavy plant.

It provides a durable, functional and stylish covered queuing solution that offers both shade and a wet weather covering. The highly effective canopy is made from fully waterproof and UV blocking fabric engineered to resist the extremes of British weather, all year round.

Qube Renewables are a supplier to the renewable energy industry with a difference. Working under the oversight of Mark Clayton (also the Managing Director at Aardvark EM) and through close collaboration with their supply chain, the Qube Renewables team designs and builds innovative solutions predominantly for the Anaerobic Digestion industry.

OMS are proud to have been a part of this melting pot of ideas for many years now having worked closely with Mark and the team in developing bespoke fabric solutions for their BioQube, QuickQube, PowerQube and LagoonQube range of products.

The latest offering to the Qube range, DryQUBE is a fabric based dry digester allowing biodegradable stackable feedstocks to be digested in a controlled anaerobic environment. These are quick to install and easy to operate requiring minimal ground works.

Each modular dryQUBE has a volume of ~500m3, ideal for ligneous wastes (e.g. straw, sawdust or green waste) needing long retention times (180 days +). The modules are entirely scalable, and can be designed to fit in any available space.

Haryana DryQube

For the past 25 years Roger Brisley through his company Timber Intent Ltd has pioneered the eco-friendlier tensile, using a traditional blend of timbers, stainless and spliced rope riggings, with natural and appropriate fabrics; his structures are always pleasing on the eye and highly practical solutions meeting his Clients’ brief.

Rogers ecological ideology was always the companies USP and their differentiator when the rest of the world was running toward plastics and steel. It is hard to deny that sewn natural fabrics are texturally and aesthetically pleasing in a way that welded PVC’s cannot hope to match.

When Timber Intent approached OMS to be their 1st Tier manufacturer we were flattered. Our knowledge of sewing operations allied to our manufacturing capacity and technical abilities with inhouse CAD-led-cutting and processing we considered our businesses a good and complimentary fit.

Hartlepool Historic Quay

It is through these close collaborations and many significant others, that OMS support their client base and in the process have gained extensive knowledge and experience in the design, manufacture and installation of all manner of engineered fabric product.

Cutting Welding Sewing

Sub contract manufacturing of

Tensile Fabric Structures & Roofs, Staging and Advertising Signage

Interior and exhibition fancies and follies

Product Development & Consultancy

Industrial equipment for civil engineering and environmental companies

Jon Morris

Has worked with fabrics since 1994 initially with Landrell Fabric Engineering, then in 1996, moved on to build and manage the Tensile Fabric production facilities at Architen Ltd.

In 2001 Jon was the founding partner of Base Structures Ltd, going on to found OMS in 2016.

Jenna Brooks

A design graduate with an accumulated 18 years experience in the fabric industry. Jenna initially worked alongside and then managed some of the best fabric structure designers in the world.

Mariusz Rowinski

Started his fabric career 34 years ago in Poland as a furrier tailoring suits for export to Russia. Since then Mariusz has managed high quality production facilities in both Poland and the UK

Mariusz's general all round knowledge and practical skill set never fails to impress and ensures customer know OMS can be relied upon to get the job done.

Next Steps...

Should you require any of the services listed above, or are unsure if we can help, then please do not hesitate to call and discuss your requirements